Our many years of expertise ensure consistent quality. We exchange or rework your wear parts and are available with uncomplicated quick service. With respect to the latest technology, your plant will be steadily more efficient than on the first day. QUALIFIBER ® always keeps your spare parts up to date and you benefit from further developments.

All components installed in your QUALIFIBER ® systems are optimally matched to their respective use and are subject to continuous further development.

Continuous further development, competent consulting – everything from a single source.

QUALIFIBER ® relies on short ways to act uncomplicated and fast. Our customers benefit from the high availability of spare parts.

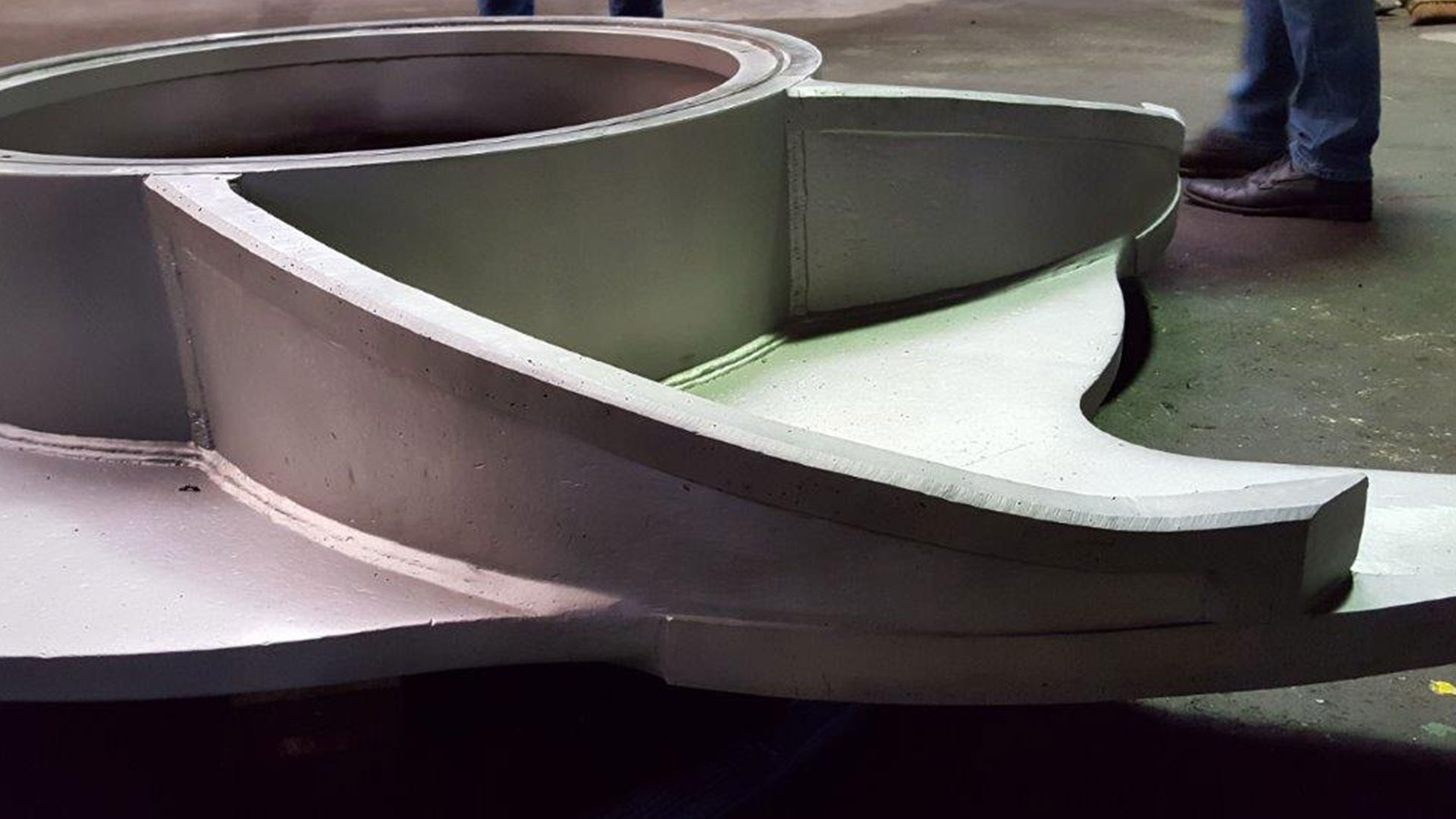

Rotore

For a stock preparation machine to work optimally in terms of technology and energy, it is important that the geometries of the individual parts fit together.

This is checked by us and if the results are good, the rotor / wear part is restored to its original geometry.

If you as a customer have the desire to optimize something, we will be happy to help you and, if necessary, adjust the rotor / wear parts accordingly and document this with a corresponding output protocol.